Micro-scale Morphological Gradients

Stochastic morphological gradients with topographical features in the micron scale can be generated by a two-step procedure, which involves a kinetically-controlled chemical-polishing procedure as the second step.

Method

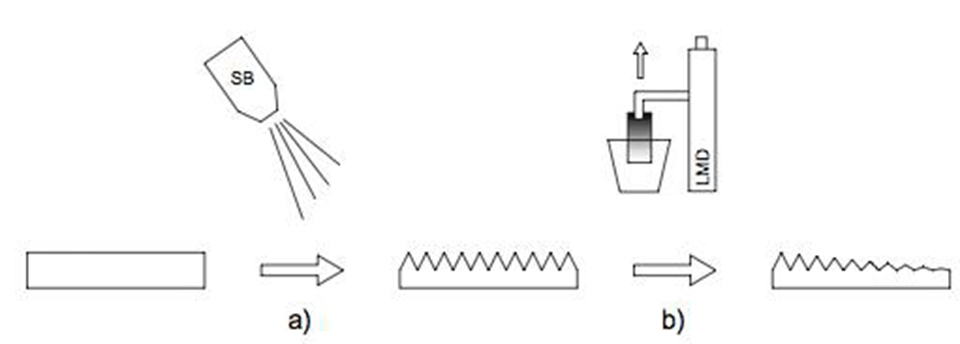

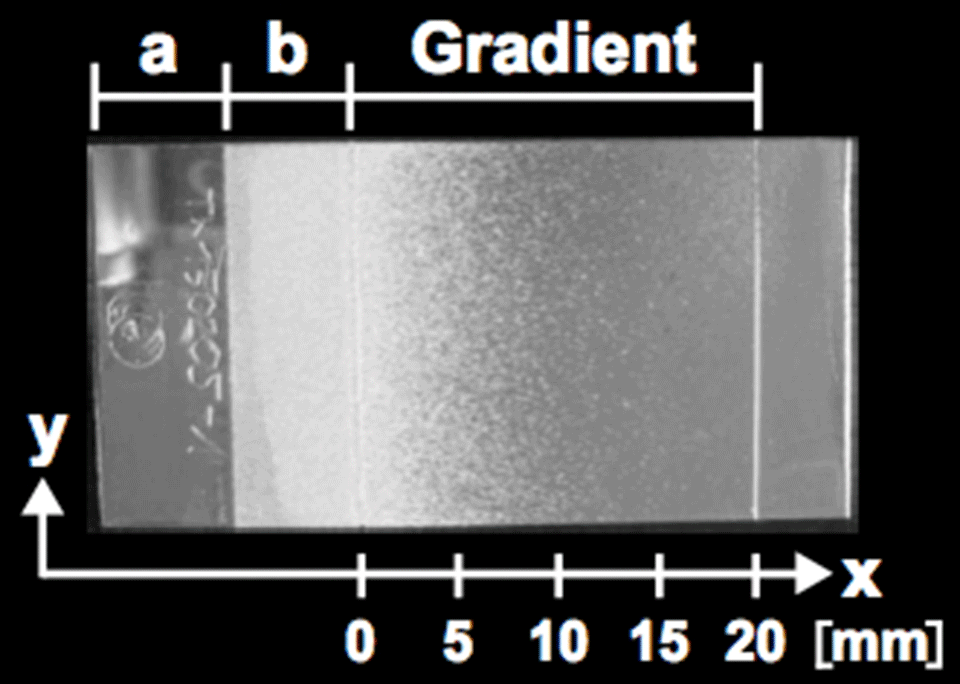

In the first step, an aluminum sheet is blasted with fractured corundum particles or zirconium dioxide beads to create a homogeneously rough surface (Fig.1, a). This step determines the maximum topographical variations of the sample. In a second step, a chemical-polishing procedure is applied to reduce the roughness as a function of distance along the sample (Fig.1, b). The degree of smoothing depends on the reaction kinetics and therefore can be controlled by the residence time of a substrate in the polishing solution. The actual roughness gradient is created by continuously withdrawing the sand- or bead-blasted sample from the solution using a linear-motion drive (Fig.2).

While aluminum is well suited to this approach, it may not be appropriate for a particular application. This issue can be solved by replicating the gradients with a polyvinylsiloxane replica material and subsequently casting an epoxy positive [external page1call_made]. These replicas can then be coated and functionalized with different materials and surface chemistries.

Cell Adhesion

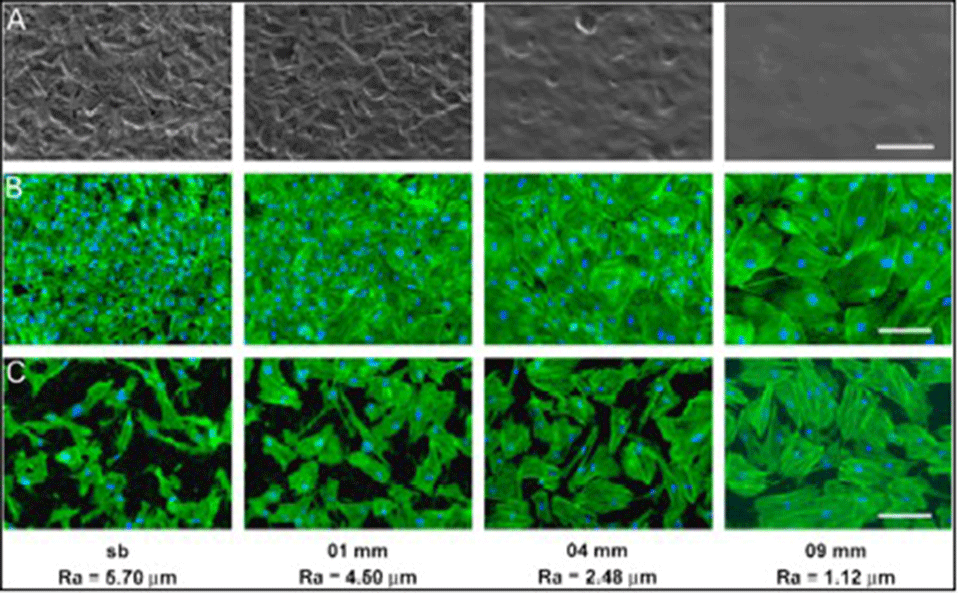

Since surface roughness is known to influence cell adhesion and proliferation, these roughness gradients have been exposed to rat calvarial osteoblasts and human gingival fibroblasts [external page2call_made]. Cell adhesion and proliferation was found to vary along the gradients, with an increasing proliferation of osteoblasts with increasing roughness and opposite behavior for the fibroblasts (Fig. 3).

References

- Kunzler, T. P.; Drobek, T.; Sprecher, C. M.; Schuler, M.; Spencer, N. D., external pageFabrication of material-independent morphology gradients for high-throughput applications.call_made Applied Surface Science 2006, 253(4), 2148-2153.

- Kunzler, T. P.; Drobek, T.; Schuler, M.; Spencer, N. D., external pageSystematic study of osteoblast and fibroblast response to roughness by means of surface-morphology gradientscall_made. Biomaterials 2007, 28(13), 2175-2182.