Aqueous Brush Systems for Practical Lubrication Applications

Macro-tribological properties of polymer brushes in solvent mixtures:

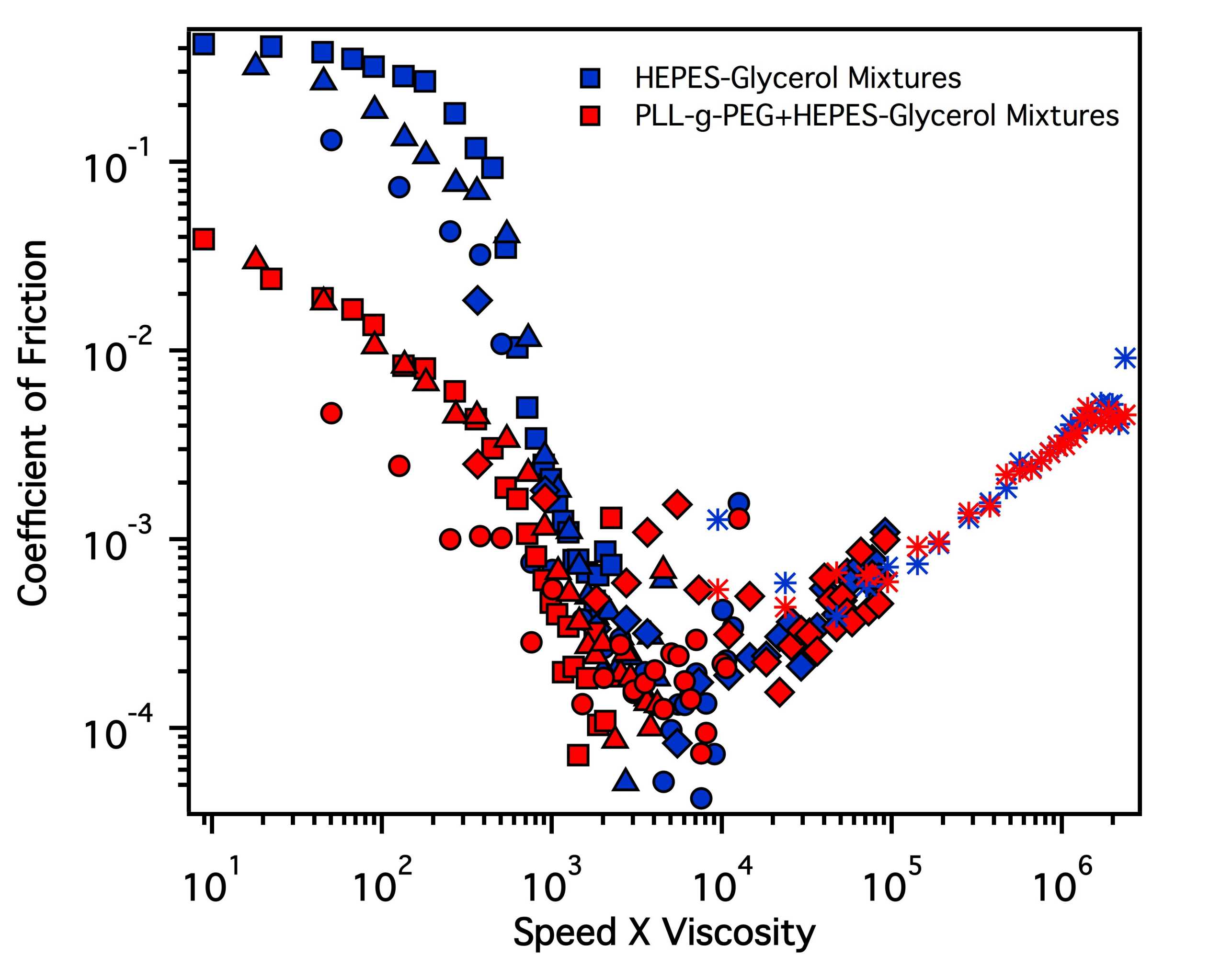

Viscosity of the lubricant plays an important role in lubricating surfaces. It influences the lubricating regime at which the tribo-pairs operate. One approach to increase the base-fluid viscosity of aqueous-brush-assisted lubrication is by using aqueous mixed solvents. Solvents such as glycerol and ethylene glycol are highly viscous, in comparison to water, and polar, and thus are miscible in the polymer-aqueous system. Polymers in solvent mixtures can combine the advantages of both co-solvents. On the one hand, the presence of water keeps the hydrophilic polymer like Poly(L-lysine)-graft-Poly(ethylene glycol) (PLL-g-PEG) and Poly(L-lysine)-graft-Dextran (PLL-g-Dextran) hydrated and reduces the friction in the boundary lubrication regime. On the other hand, the bulk viscosity of the solvent is enhanced, due to the presence of viscous co-solvent (like glycerol or ethylene glycol), and can assist in increasing the load-bearing capacity of the lubricant by hydrodynamic forces1 (Figure 1).

Nano-tribological properties of polymer brushes in solvent mixtures:

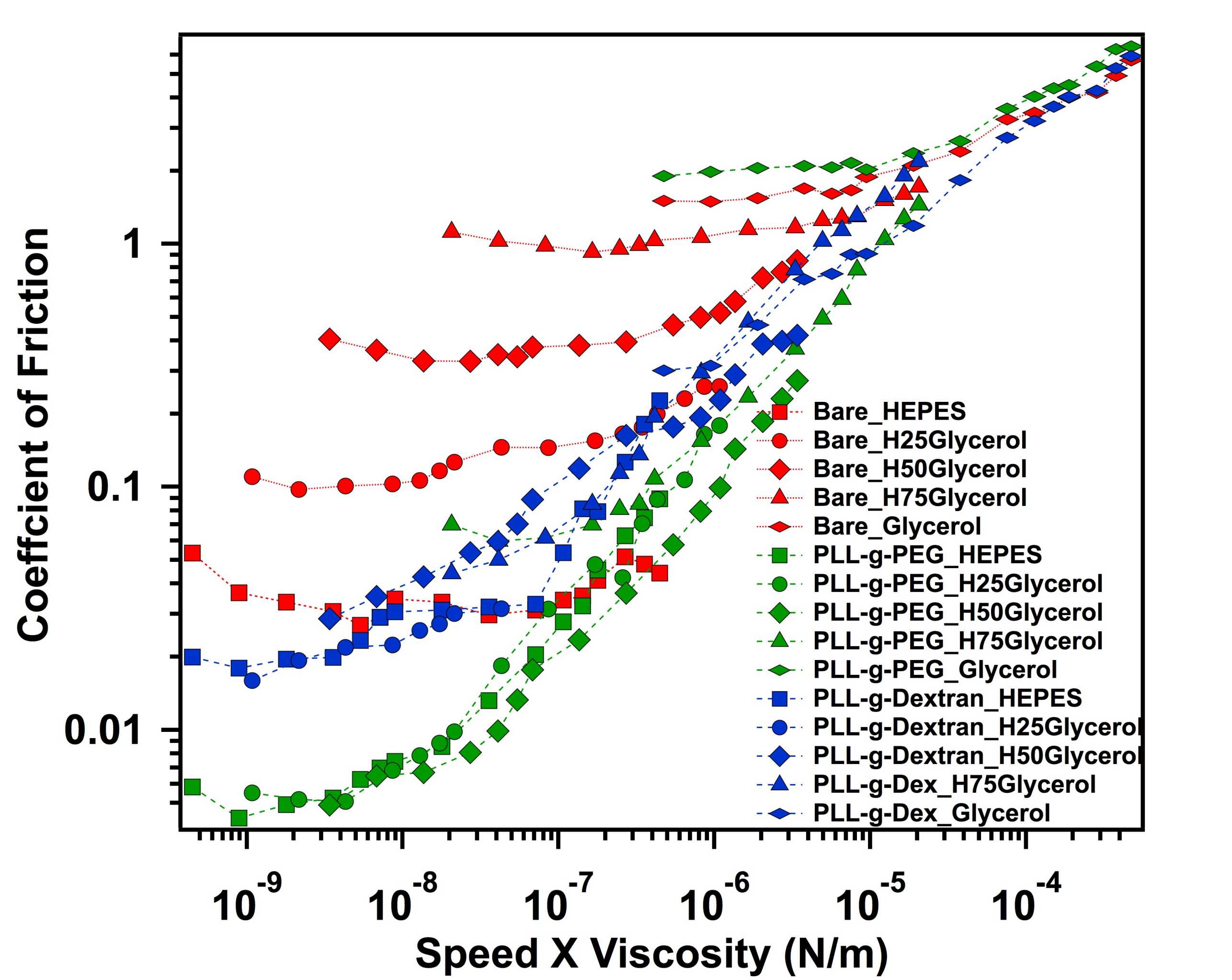

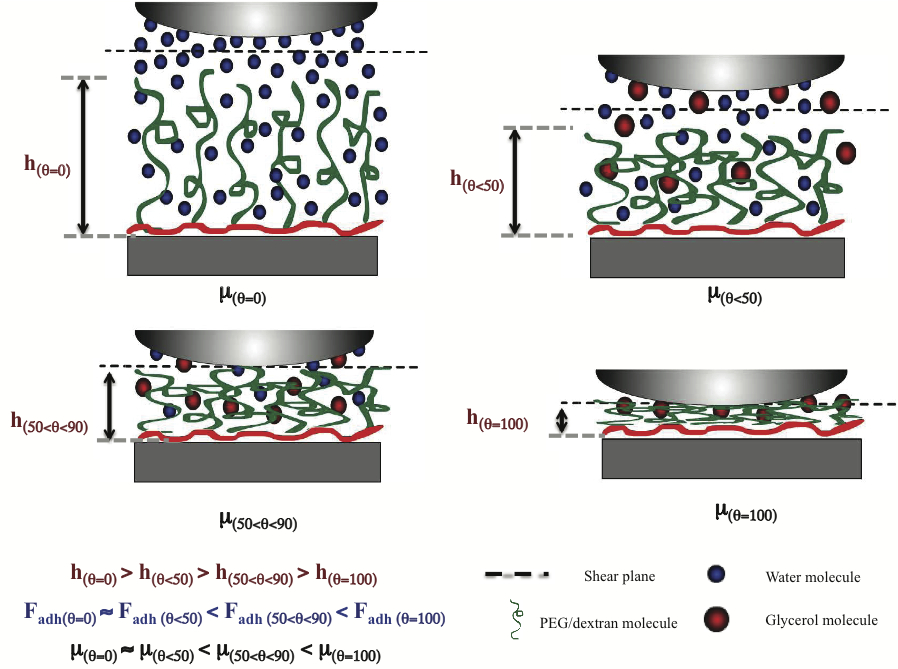

However, at the nano-scale, in the absence of wear, the frictional properties of polymer brushes are influenced by the conformation of the brushes, which is highly affected by the solvent quality. Higher degree of interpenetration of polymer chains and reduced polymer-solvent interaction strength leading to a viscous, collapsed, and less lubricious film in theta or poor solvents result in higher friction forces in comparison to good solvents under relatively similar compressive loads. Nano-scale stribeck curve for bare silica surface is obtained in aqueous glycerol mixtures mixtures and is compared with nano-scale stribeck curves obtained for PLL-g-PEG and PLL-g-Dextran brushes (Figure 2). Clear transition from boundary to hydrodynamic regime as a function of speed multiplied by viscosity is seen for bare surfaces. However, friction coefficient for polymer brushes is influenced by both polymer brushes and solvent viscosity from the lowest measured velocities2.

Solvent interactions with polymer and the free energy of mixing between water and the co-solvent govern the structural properties of the polymer brushes3,4. The presence of the interfacial fluid film layer is shown to play an important role in delaying the increase in friction forces, inspite of a continuous collapse of the polymer film, with increase in volume percentage of the poor solvent in the solvent mixture.

References:

- Prathima Chandra Nalam; Polymer Brushes in Aqueous Solvent Mixtures: Impact of Polymer Conformation on Tribological Properties. PhD Thesis, No. 20211, , ETH Zürich, 2012

- Two-fluid model for the interpretation of QCM response: Tuning polymer brushes using mixed. Prathima C Nalam, Leonid Daikhin Rosa Espinosa, Jarred N. Clashom, Michael Urbakh and Nicholas Spencer. The Journal of Physical Chemistry C 177 (9), 4533.

- Impact of solvation on equilibrium conformation of polymer brushes in solvent mixtures. Rosa Espinosa Marzal, Prathima C Nalam, Sreenath Bolishetty, Nicholas D. Spencer. Soft Matter, 2013, 9, 4045-4057.