Polymer Analogs to Biolubrication Systems

Novel Materials for Exploring Cartilage Tribology and Exploiting its Mechanism

Background

Among the connective tissues in our body, cartilage shows the poorest healing potential due to an absence of blood vessels and scarce cells (chondrocytes) in a thick extracellular matrix with poor capacity to migrate to the zone of injury. Current therapy techniques are able to improve the patient’s situation, but bear the risk of causing more damage to the joints when damaged cartilage is removed (chondroplasty) or holes are drilled into the underlying bone tissue (microfracture). Furthermore, in many cases the transplanted tissue is rejected when cavities are filled with a plug of cartilage and bone from a donor (osteoarticular allograft) or when a cartilage suspension (cultured either from own cartilage, ACI, or from a juvenile donor, denovo NT) is injected. A strong demand for less invasive and more efficient therapeutic methods is arising especially with higher numbers of sport injuries and an increasing average life expectancy.

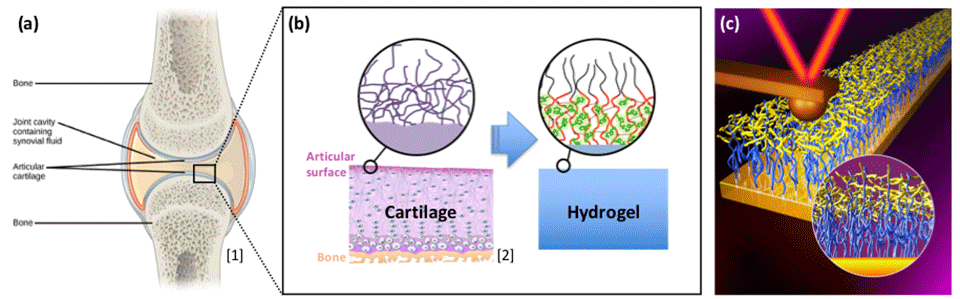

Articular cartilage (Figure 1a) is a connective tissue that covers the bone surface in the synovial joints of mammals. The structure of this outstanding natural material developed over millions of years into a specialized architecture that not only supports the body load acting on the joints but also protects opposing bone surfaces from direct contact along with lubricating the movement in synovial joints. In comparison to industrial, man-made tribological systems, the lubrication of cartilage does not mainly depend on a velocity and force dependent fluid film formation between contacting surfaces but is driven largely by polymer chain interactions surrounded by a water-based lubricant.

Objectives

- Investigation of the Relative Mechanistic Roles of Individual Components of Cartilage

- Fabrication of Biomimetic, Polymeric, highly Lubricious, Highly Wear-Resistant Materials that Function in an Aqueous Environment

- Generation of Design Criteria and Potentially Initial Prototypes of Lubricious Biomaterials for Temporary or Permanent Implantation

Methodologies

Synthetic Approaches

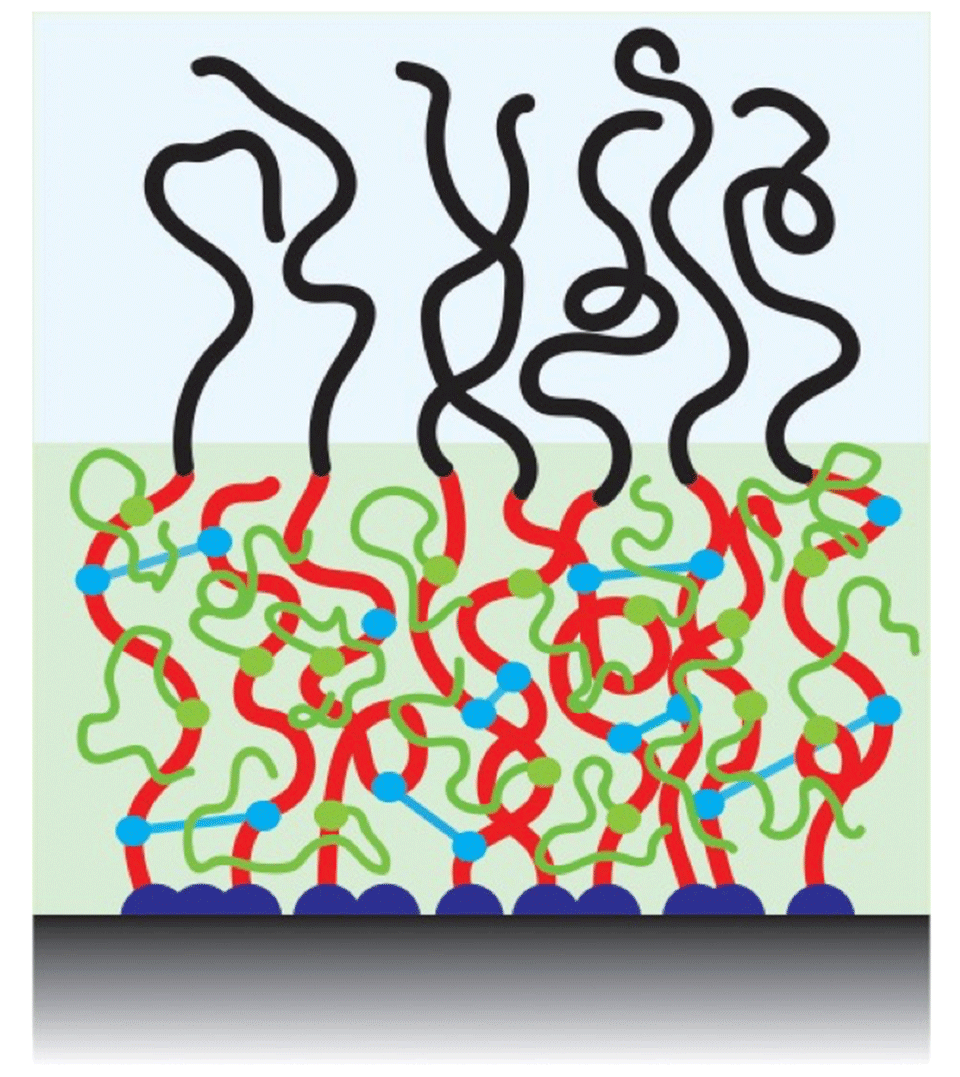

The aim of this project was to fabricate biomimetic polymeric materials that are highly lubricious, highly wear-resistant and work in an aqueous environment (Figure 1b). Therefore, orthogonally functionalizable copolymer brushes were grown from photo-cleavable initiators[3] on a silicon oxide surface by means of atom-transfer radical polymerization (ATRP) (Figure 2). Grafted macromolecular chains are designed to contain reactive centers utilized for chemoselective orthogonal post-polymerization modification (PPM) and for controlled crosslinking of the polymeric network.

Contact: Dr. Matthias Dübner

In Situ Monitoring

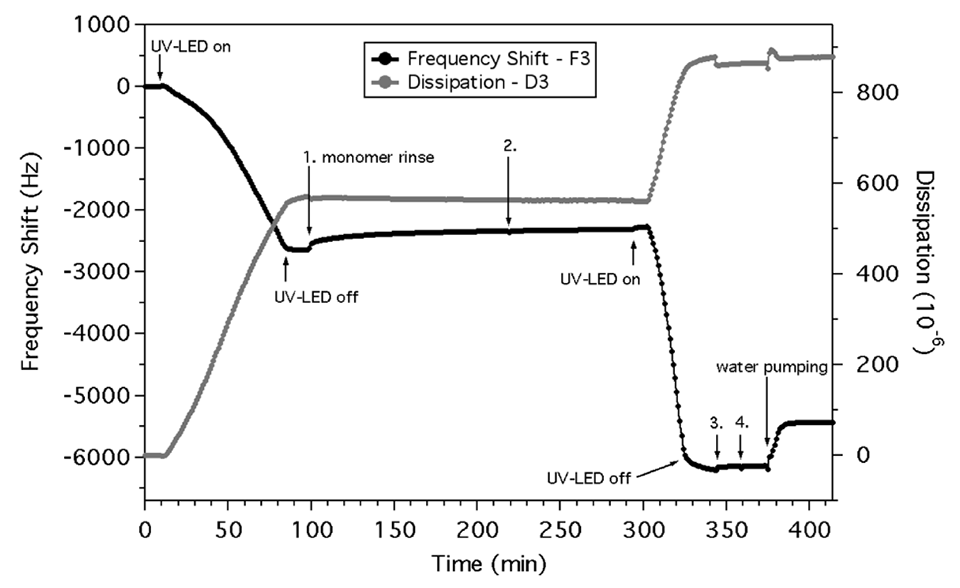

The idea of flow synthesis has wisely been used by polymer chemists too in radical polymerisation using different types of flow-reactor. Since our group is actively involved in the construction of polymer brushes from Si-surface using different types of radical polymerization, it will be interesting to monitor the reactions in situ by the use of quartz-crystal microbalance (QCM). Interestingly, the very first surface UV-initiated radical polymerization carried out in our lab[4] used a flow system coupled with a quartz-crystal microbalance with dissipation measurement (QCM-D) for in situ monitoring of the polymerization (Figure 3). The frequency drops down and attain a constant value repeatedly depending on whether the UV source was switched on or switched off. The decrease in frequency indicates the onset of polymer growth while the constant frequency indicates bulk surface without polymerization. The on-off polymerization in response to the illumination of the UV source was clear evidence to support the efficacy of QCM-D.

Contact: Dr. Joydeb Mandal

Hydrogels

Hydrogels are a soft class of materials that consist of a three-dimensional, crosslinked polymer network with large amounts of water tightly incorporated in the mesh. Their exceptionally high water content in combination with their mechanical properties and intrinsic lubricity makes them good substrate materials to construct a polymeric analogue of articular cartilage. One assumes the surface of a hydrogel to consist of polymer chains of different lengths and crosslinking density. However, no clear picture of a detailed structure of these exceptional surfaces exists to-date. In order to shed light on its architecture, this work aims to investigate the gel surface with atomic force microscopy and tribological tests. Here, a change in the polymer conformation on the surface layer of gels is introduced by varying its moulding condition and its environment. In order to visualise different states of polymeric surface structures, another goal of this project is to explore new approaches to directly image and characterize the hydrogel surface.

Contact: Yvonne Gombert

Mechanics

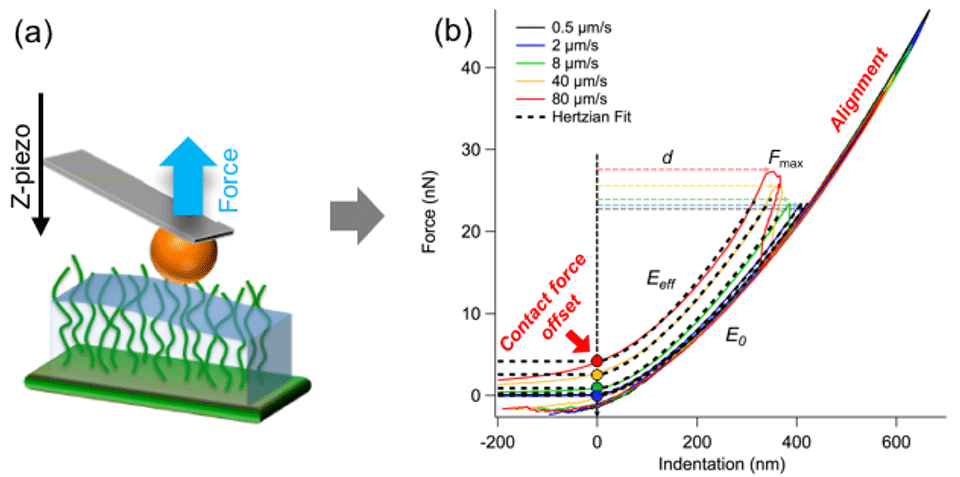

Hydrogels and brush-like polymeric materials mimic various cartilage properties, such as a biphasic structure and the ability to confine liquid therein. Increasing the strain rates of such biphasic materials shows stiffening effects, which can be attributed to “fluid load support” – a phenomenon in which part of the applied stress (load) is carried by the fluid confined within the material. It is believed that fluid load support is directly related to the hydration and good lubrication properties of these materials.[5] To analyse rate-dependent surface properties of fabricated polymeric materials, methods such as indentation as well as tribotests at a range of scales from macro to nano are being performed throughout the project. Since tribological behaviour greatly depends on the topmost, nanoscale layers of materials, colloidal-probe AFM nanoindentation is being employed to elucidate the properties of the first 10-1000 nm. For this purpose, a 2-step rate-dependent indentation method was developed to enable precise determination of contact point that can be obscured by the viscous squeeze-out forces ahead of the contact during an indentation at finite rates in liquid (Figure 4a). The method presents an enabling approach to the determination of the contact point, elastic and effective contact moduli, relaxation times as well as adhesion properties during indentation of soft matter in liquid environments (Figure 4b).

Contact: Dr. Rok Simic

Acknowledgements

external pageEuropean Research Council (ERC)call_made

European Union’s Horizon 2020 research and innovation programme (Grant Agreement No. 669562)

References

[1] http://cnx.org/resources/774d7d9189659b105ccc3f5eb7812e7eed9a9734/Figure_38_03_03.jpg (2016)

[2] C. Matta and R. Zakany, Frontiers in Bioscience 2013, Scholar, 5, 305-324.

[3] C. Kang, R. Crockett, N. D. Spencer, Polymer Chemistry 2016, 7, 302-309.

[4] R. Heeb, R.M. Bielecki, S. Lee, N.D. Spencer, Macromolecules 2009, 42, 9124-9132.

[5] E.D. Bonnevie et al., Journal of Biomechanics 2012, 45, 1036-1041.