Role of Viscous Solvent Confinement in the Tribological Behavior of Polymer Brushes

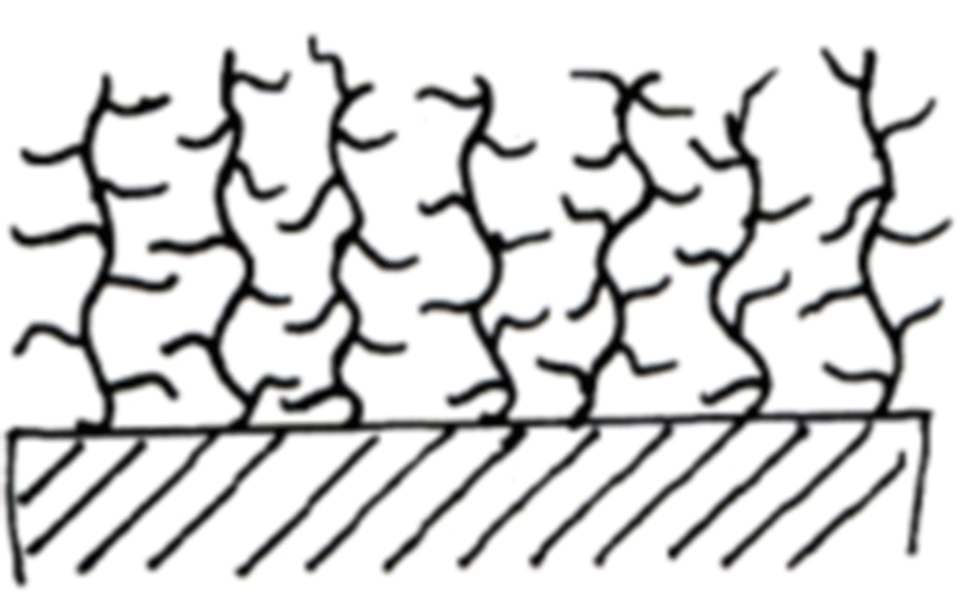

The aim of this work is to elucidate the phenomena that govern the low friction and wear of oil-compatible polymer-brush coatings. Figure 1 shows the schematic architecture of one of the investigated polymer brushes poly(dodecyl methacrylate) (designated as P12MA). We have used an extended surface forces apparatus (eSFA) to measure the surface forces between two mica surfaces coated with P12MA brushes in three solvents with different viscosities (toluene, hexadecane and EO500 oil), and to determine the swelling ratio in each solvent. Both eSFA and nanoindentation experiments have been used to investigate the mechanical behavior of the polymer brushes, the relaxation phenomena involved, and the effective confinement of viscous fluids within the brush.

Polymer brushes consisting of micrometer-long P12MA chains can impart very low coefficients of friction to surfaces sliding in oil [1,2]. Under harsh tribological conditions, however, this behavior can only be maintained for long periods of time in the presence of highly viscous fluids, which appear to protect the brushes from wear. This behaviour is analogous to the lubricating mechanism in synovial joints, inasmuch as the confinement of pressurized synovial fluid in cartilage is partially responsible for the low wear rate of the system. Structures such as that of P12MA brushes, which are rich in side-chains and possess long backbones, serve as a flow scatterer and enable lubricant confinement within the loaded zone [3]. High viscosity, high sliding or loading speed and long polymer brushes all enhance confinement. Upon lubricant confinement, the apparent elastic modulus is larger than the equilibrium value and it is the fluid that principally carries the applied load, protecting the brushes from wear. It has to be remembered that the liquid is pressurized temporarily and that the load support, as well as the low coefficient of friction, is only observable when the migration of the contact area occurs at sufficiently high speeds. This explains the observed low wear rates observed in tribological experiments in viscous liquids.

The goal of the current studies is to elucidate the behavior of polymer-brush lubrication systems by combining the mentioned experimental techniques with Finite Element modeling studies, and to move towards the establishment of design rules for the brush-based lubrication of machines. We plan to investigate both aqueous and oil-based brush systems, and to this end we will be synthesizing appropriate brushes, in a variety of grafting densities and molecular weights and various branching architectures, in order to investigate the influence of this factor on the confinement behavior.

References

- Bielecki RM, Benetti EM, Kumar D, Spencer ND (2012) "Lubrication with Oil-Compatible Polymer Brushes". Tribol Lett 45 (3), 477-487.

- Bielecki RM, Crobu M, Spencer ND (2013a) "Polymer-Brush Lubrication in Oil: Sliding Beyond the Stribeck Curve". Tribol Lett 49 (1), 263-272.

- Rosa M. Espinosa-Marzal, Robert Bielecki, Nicholas D. Spencer. Understanding the role of viscous solvent confinement in the tribological behavior of polymer brushes: a bioinspired approach. Submitted to Soft Matter, 2013.