Bulk Polyphosphate Glasses as Models for ZnDTP Tribofilms

Introduction

One of the most successful and long-lived classes of lubricant additives are the zinc dialkyldithiophosphates (ZnDTPs), known for their antioxidant, corrosion inhibition, and antiwear properties. The uniqueness of ZnDTP lies in its ability to form thin glassy reaction layers at the sliding interface that, thanks to their ability to become thicker and harder where the contact pressure is higher and to adapt to almost every stress condition, are very effective in preventing wear.

While it is commonly accepted that the antiwear effectiveness of ZnDTP is correlated with its ability to form a thick polyphosphate film, very little is known about the mechanical and tribological properties of bulk polyphosphate glasses.

The characterization of the surface chemistry of such glasses turns out to be a key step for understanding their mechanism of action.

Chain-length Identification Strategy in Polyphosphate Glasses

The surface chemistry of the synthesized glasses (Figure 1) has been investigated by means of X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary-ion mass spectroscopy (ToF-SIMS). The aim was to design an analytical strategy that could serve as a basis for an accurate interpretation of more complex spectra such as those of the polyphosphates glasses formed by lubricant additives under extreme high-pressures and at high temperatures.

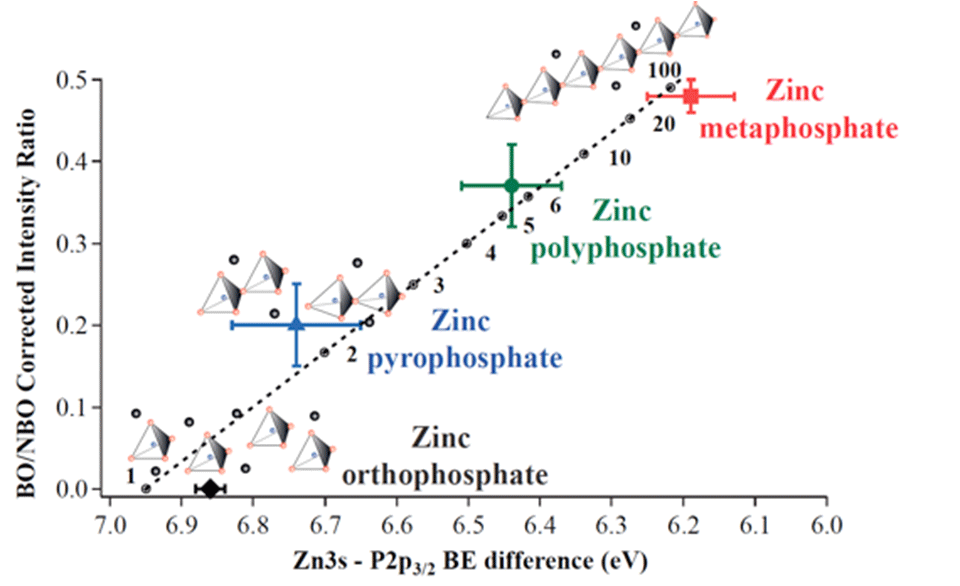

The identification of the chain length of zinc polyphosphates by XPS could be achieved on the basis of the integrated intensity ratio of the bridging (P-O-P) and non-bridging (P=O and P-O-M) oxygen peaks used for fitting the oxygen 1s signal, the shift of the P 2p3/2 signal towards lower binding energies (Figure 2).

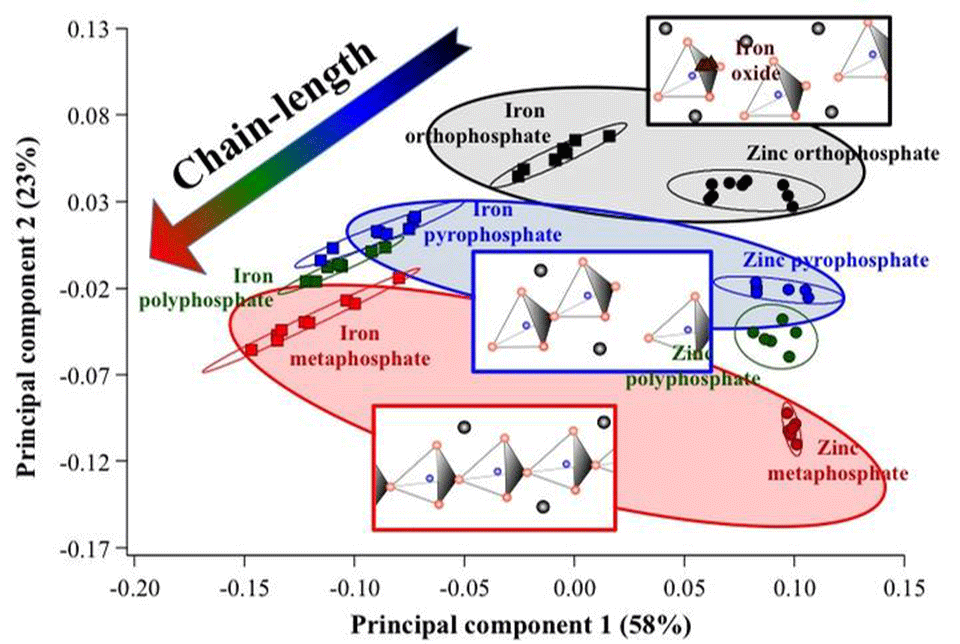

ToF-SIMS can provide complementary information to XPS, thanks to the monolayer surface sensitivity combined to an excellent lateral resolution (in the order of 100 nm). The ToF-SIMS spectra were also shown to be a powerful method for discriminating the phosphates of different chain lengths. In Figure 3 the principal component analysis (PCA) was used to successfully discriminate between the different composition polyphosphates.

Tribochemical Behavior of Polyphosphate Glasses

A protocol for tribological tests on the model compound polyphosphate discs samples has been established. The tests were carried out using steel balls as counterpart in a poly-a-olephine (PAO) bath at room temperature.

Tribological tests on the model compound polyphosphate discs were carried out using steel and quartz balls as counterparts in a poly-α-olefin (PAO) bath at room temperature. The coefficient of friction and the wear rate measured in the case of zinc polyphosphates were found to be lower compared to iron polyphosphates and to decrease with increasing initial chain-length.

With the established chain length identification method, small-area XPS analysis of the discs showed that the long-chain-length polyphosphates are depolymerized in the wear track as a consequence of a tribochemical reaction.

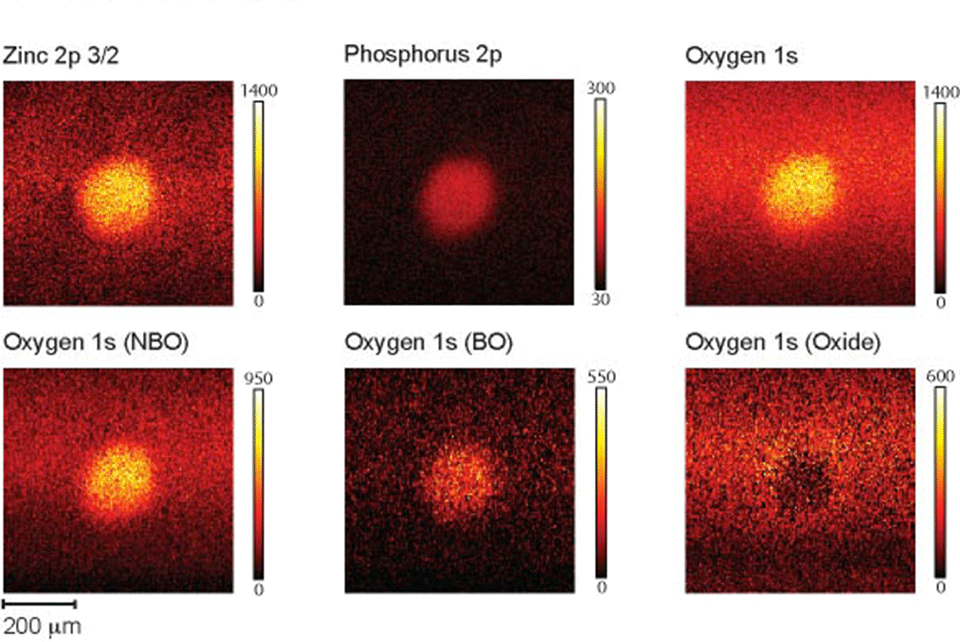

Imaging-XPS analyses of the steel balls (Figure 4) following tribological tests on polyphosphate discs showed the formation of a glassy, phosphorus-containing transfer film in the contact area, reducing friction and wear of the steel ball.

These results led to the conclusion that a third body mechanism is governing wear in the steel-versus-polyphosphate tribopair.

References

- Crobu M., Rossi A., Mangolini F., and Spencer N. D.: Tribochemistry of Bulk Zinc Metaphosphate Glasses. Tribol. Lett. 39, 121-134 (2010).

- Crobu M., Synthesis, characterization and tribochemical behavior of polyphosphate glasses, PhD Thesis No. 20251, ETH Zurich, Zurich, 2012.

- Crobu M., Rossi A., Mangolini F., and Spencer N.: Chain-length-identification strategy in zinc polyphosphate glasses by means of XPS and ToF-SIMS. Analytical and Bioanalytical Chemistry, 1-18 (2012).

- Crobu M., Rossi A., and Spencer N.: Effect of Chain-Length and Countersurface on the Tribochemistry of Bulk Zinc Polyphosphate Glasses. Tribol. Lett. 48, 393-406 (2012).

- Crobu M., Rossi A., and Spencer N. D.: ToF-SIMS of polyphosphate glasses. Surf. Interface Anal. (2012).