Combinatorial Tribological Measurement

In both chemical and materials research the combinatorial approach and high-throughput screening lead not only to the faster development of drugs and materials but sometimes also to the discovery of unexpected properties of a compound. We have introduced the basic concept of this approach into research and development for lubricant-additive systems.

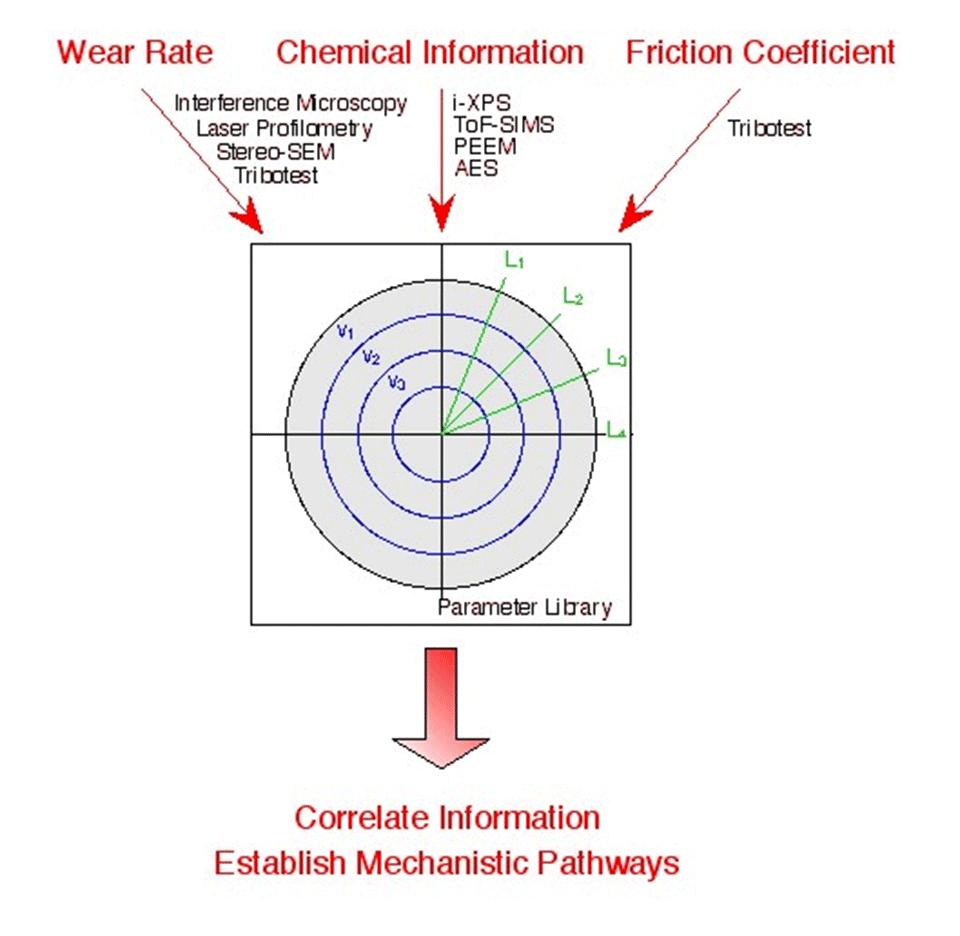

In a given tribological system it is important to understand the various reactions that occur between a lubricant additive and the tribopair, as a function of the applied conditions (load, relative velocity, temperature, for instance). So far it has been a time-consuming process to explore this vast array of variables; the introduction of high-throughput-screening tribometry would speed up the exploration of this large parameter space. The combinatorial approach is thus very important not only for fundamental research but also has great potential for industry, since it rationalizes tribological testing. Various tribological test conditions can be tested in a single experiment, producing a set of spatially separated areas on the same sample. This procedure can be applied to dealing with the behavior of many different additives and oil formulations.

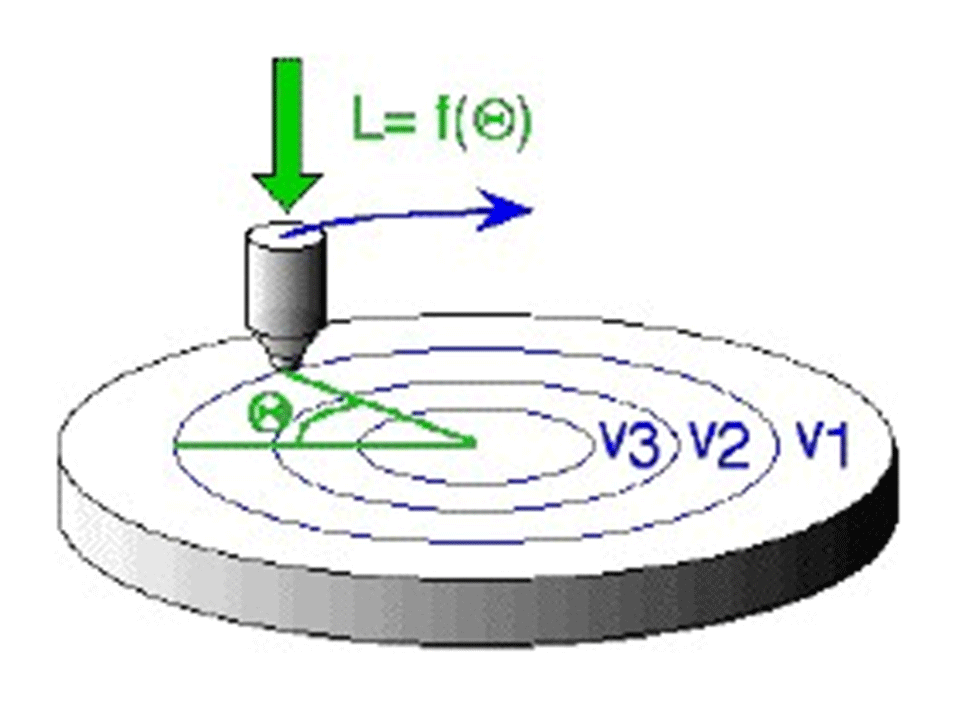

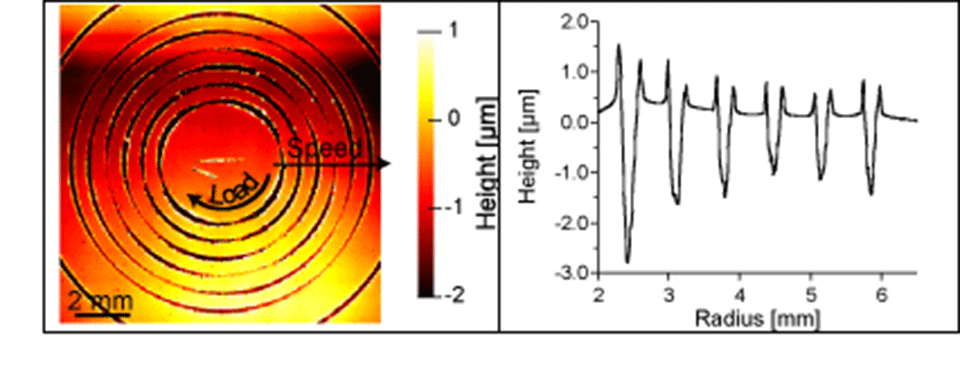

On a single sample, various tribological tests are combined. The spatial variation of the applied set of conditions is used to produce a parameter library. We have developed three kinds of tests: the combinatorial step test with different contact pressure at different annuli, whereby tribostressed regions were produced by a stepwise change of the radius (Figure 1).

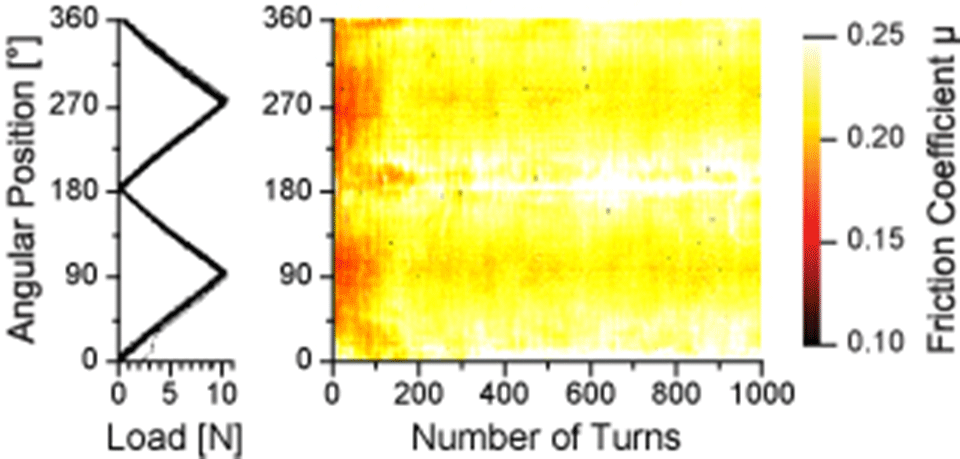

Second, the combinatorial oscillating-load test, where different contact pressures were applied in dependence of the angular position on a single annulus (Figure 2).

Third, the wear test where different contact pressures were tested in dependence on the angular position of the annulus, with several sliding speeds on different annuli.

The results of the subsequent spatially resolved surface analysis (e.g. imaging-XPS, AES or ToF-SIMS) could be correlated with the applied conditions and the tribological results (Figure 4).

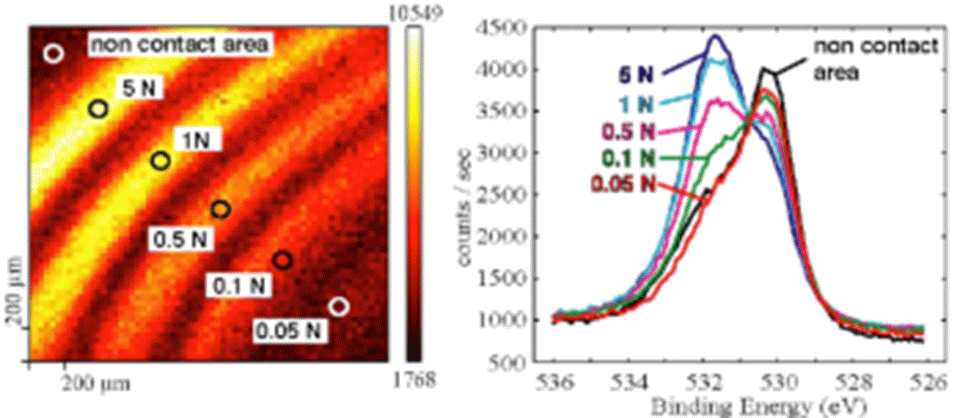

A parameter library has been produced, varying the load in a ball-on-disc tribotest (immersed in a solution of 1-wt% ZnDTP in decane) from 0.05 to 5 N as a function of the radial position on the disc. The sample has been analyzed by means of imaging X-ray photoelectron spectroscopy (i-XPS). This method provides both the elemental distribution and the chemical state of the elements, giving an indication of the nature of the protective film formed by the tribochemical reaction.

On the left-hand side of Figure 5 the chemical-state map shows the correlation of the O1s spectra with a signal characteristic of phosphate. The various wear tracks are visible. On the right-hand side, the detailed O1s spectra clearly show the increase of the phosphate peak at 531.8 eV with increasing load.

References

- Heuberger R., Rossi A., and Spencer N.D., Pressure Dependence of ZnDTP Tribochemical Film Formation: A Combinatorial Approach,

Tribology Letters, September 15, 2007, vol.2, page 209-222, ISSN 1023-8883, DOI 10.1007/s11249-007-9267-0 - Rossi A, Eglin M, Piras FM, Matsumoto K, Spencer ND, Surface analytical studies of surface-additive interactions, by means of in situ and combinatorial approaches, Wear, 256 (6), 578-584, 2004.

- M. Eglin, A. Rossi, N. D. Spencer, A combinatorial approach to elucidating tribochemical mechanisms, Tribology Letters, 15(3), 193-198, 2003.

- M. Eglin, A. Rossi, N. D. Spencer, XPS surface analysis of tribostressed samples in the presence of i-ZnDTP using a combinatorial approach, Tribology Letters, 15(3), 199-209, 2003.

- M. Eglin, A. Rossi, N. D. Spencer, Additive-Surface Interaction in Boundary Lubrication: A Combinatorial Approach, Trib. Ser.40, "Boundary and Mixed Lubrication: Science and Application", 49-57, 2002.